| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : JIATUO CHINA

Model Number : JTPP110

Certification : IS CEO

Place of Origin : CHINA

MOQ : 1 SET

Price : Negotiable

Delivery Time : 30-40days

Packaging Details : plastic film

Strap Material : PP Recycle Material/New Raw Material

Name : PP Strap Making Machine

Strap Width : 5-19mm

Strap Color : Red/ Green/ Black/ Yellow/ White

Thickness : 0.3-1.2mm

Motor power : 37kw

Total equipment power : 100KW

PRODUCT DESCRIPTION

The company has more than 30 years of experience in the strapping equipment manufacturing industry in China. It has a professional R&D team, sales team, production plant, imported processing equipment from Germany, and technical personnel often go abroad for further study and learning. It has more than 50 patented products. In the Chinese packaging industry, our company has a good reputation, advanced technology, and high-end products, and always ranks first. We can provide customers with better equipment and produce higher-end products.

1.Polypropylene (PP) as the main raw material, material: polypropylene wire drawing grade resin, because of its good plasticity, fracture pull Strong strength, resistance to bending fatigue, low density, good tensile impact performance, easy to use and other advantages, has been in various fields In a wide range of roles.

2,.PP strapping tape is suitable for: suitable for all kinds of packaging machines in all walks of life (semi-automatic, automatic, manual baler)

3,.Features of PP strapping tape production line: energy saving and environmental protection, fast line speed, low failure rate, simple operation, PLC control, advanced technology, etc.

4.Color of PP strapping tape: bright color, yellow, white and black and other colors, you choose

5.LOGO: according to customer requirements and samples, the production of printing, printing ICONS and other special packaging belt.

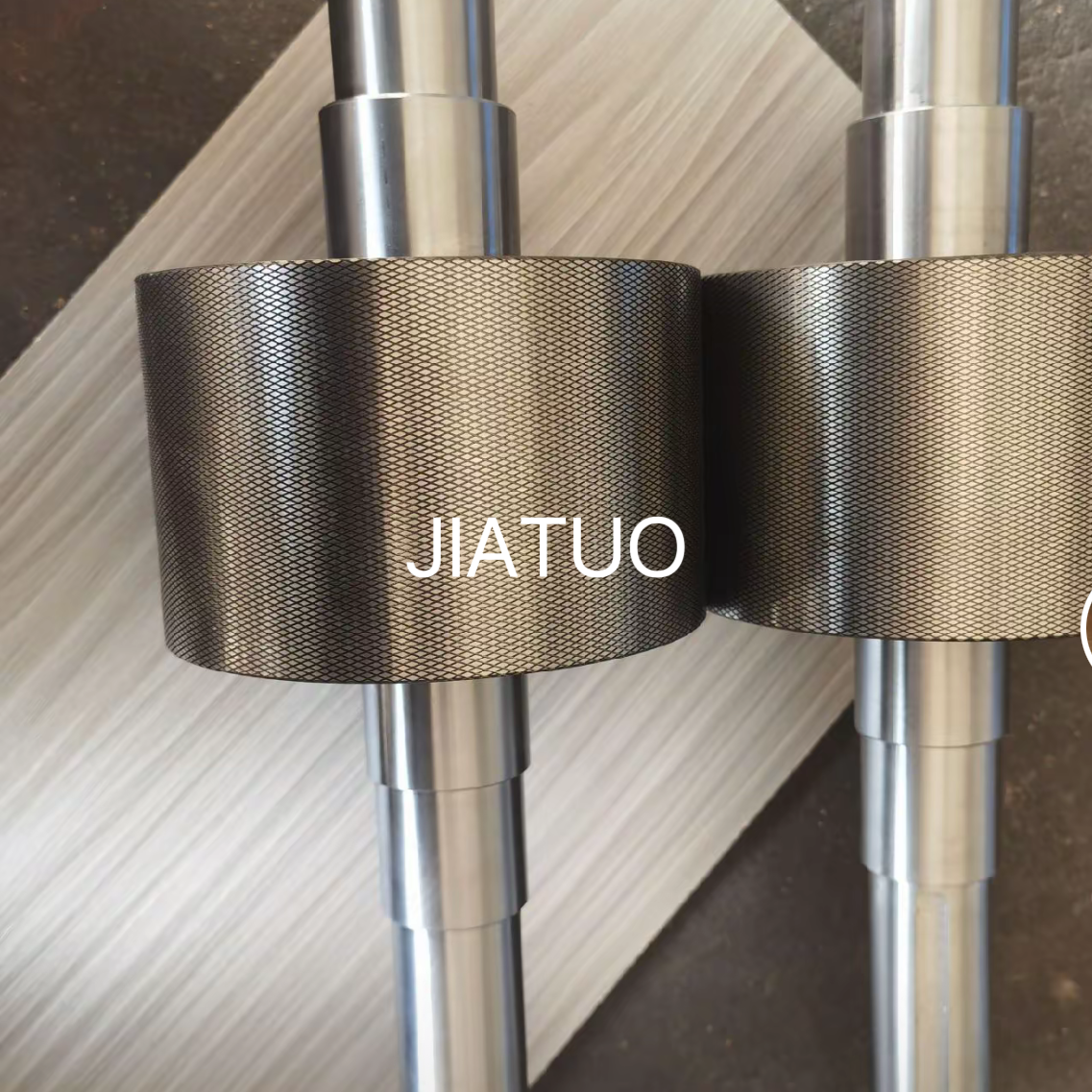

Embossing wheel for PP strapping production equipment:

1. After nitriding, the surface hardness of the embossing wheel can reach 60 degrees after heat treatment, which is strong and durable. The surface of the packing tape pressed by this embossing machine has clear lines and sufficient roughness.

2. The upper and lower flower wheels of the embossing machine are equipped with synchronous gears to ensure the synchronous rotation of the upper and lower sides, ensure that the patterns on both sides of the packing belt are completely matched, and increase the beauty and transparency of the packing belt.

3. There is a fixed gap when the upper and lower flower wheels are assembled and will never collide, prolonging the service life of the embossing wheel.

Remarks: The embossing wheel is a customized product, and it can’t be returned after the pattern is confirmed.

| Parameter | Value |

|---|---|

| Plastic Processed | PP |

| Applicable raw materials | Recycled Material And Polypropylene |

| Gearbox | 200#(GUOMAO) |

| Paper core diameter | Ø200*180mm |

| Speed | 260-300m/min |

| Strap Color | Red/ Green/ Black/ Yellow/ White |

| Strap Width | 5-19mm |

| Feeding bucket | 100KG |

| Screw diameter (mm) | 110*3300mm |

Oven process of PP strapping equipment:

1. There are six heating tubes inside the oven, and the unique oven hot air circulation mode makes full use of thermal energy to reduce power loss.

2. High temperature resistant silicone seal to keep the oven super tight.

3. Special high-efficiency stainless steel electric heating tube, heating quickly and durable.

4. Heating again to shrink the packing belt in the oven, and the straightness of the output packing belt is more standardized.

|

|

Plastic Machinery PP Polypropylene Strapping Equipment With 100-600KG/24 Extrusion Capacity Images |