| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

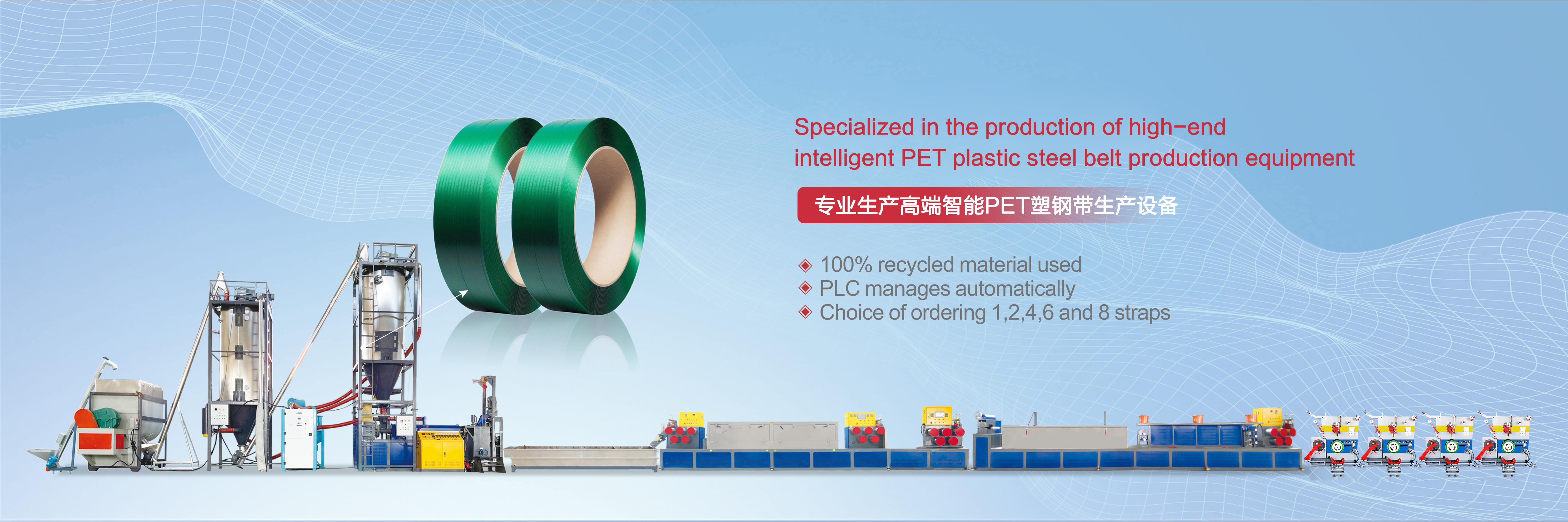

Brand Name : PET plastic steel belt production equipment

Model Number : JTPET-100

Place of Origin : CHINA

Certification : IS CEO

MOQ : 1 SET

Price : Negotiable

Packaging Details : plastic film

Delivery Time : 50-60days

Weight : 18000KG

Advanced technology : YES

Voltage : 380V/50HZ (customized )

Speed : 200-260m/min

Paper tube size : GUOMAO

Total power : 250KW(Power For Operation:120-120KW)

Raw material : PET Bottle Flake Material, 100% Broken Material

Automatic rewinding : YES

1.The extruder uses a special PET screw with unique parameter design. The screw has a unique separation and mixing effe ect to ensure the uniform plasticization of the raw materials. It has the advantages of large extrusion, good plasticization,high hardness, high wear resistance, etc.

2.The three-dimensional folding super !arge area filter device, the unfolded area of the filter screen is 30 times larger than tl the area of the traditional flat filter screen; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.

3.The rotating honeycomb dehumidification drying system is used to dry the raw materials.

4.The dew point of -50°C ensures that the moisture content of the raw materials is ≤50PPM, and has the effect of solid-pha ase polycondensation and viscosity increase.

stable, and the width and thickness fluctuations are much smaller than national standards;

5.The equipment adopts a unique double-stretching process, which has good rigidity and stable width, which improves the t tensile strength of the finished product.

6. High-precision components make the product quality Unique oven circulating heating system, internal reciprocating winding method, making full use of heat energy to

greatly r reduce power loss.

7.ToThe unique circulating cooling system and multiple sets of shaping guide rollers make the packing belt cooler and shrinl nk more fully, the product is more stable, and the size is more accurate.

8.ToThe five-roller traction system has stable traction, makes the equipment run smoothly, reduces the failure rate, and red duces the post-maintenance cost by 60%.

9.ToThe high-precision special embossing and pressing device, the pressure is adjustable, the embossing wheel can be sy ynchronized up and down, the embossing is clear and beautiful, and the product quality is comparable to that of Europe, America, Japan and South Korea.Constant force rewinding system, unique design paramet ters, in line with high output, excellent reeling effect, flat and beautiful sides on both sides.

10. The rewinding machine adopts double-station rewinding device, which is easy to operate and easy to change the reel.

11. It can be produced entirely with 100% bottle flakes, and the quality of the finished product can be compared with brand ne ew materials.

PET plastic steel strip specification table

| Model | Width | Thickness | Pull | Gross weight | net weight | net weight | Length |

| PET-0950 | 9.0mm | 0.50mm | >150kg | 20kg | 18.5kg | 200/406mm | 3400m |

| PET-1050 | 10.0mm | 0.50mm | >180kg | 20kg | 18.5kg | 200/406mm | 2720m |

| PET-1250 | 12.0mm | 0.50mm | >210kg | 20kg | 18.5kg | 200/406mm | 2500m |

| PET-1260 | 12.0mm | 0.60mm | >220kg | 20kg | 18.5kg | 200/406mm | 2300m |

| PET-1360 | 13.0mm | 0.60mm | >250kg | 20kg | 18.5kg | 200/406mm | 1850m |

| PET-1660 | 16.0mm | 0.60mm | >320kg | 20kg | 18.5kg | 200/406mm | 1480m |

| PET-1670 | 16.0mm | 0.70mm | >370kg | 20kg | 18.5kg | 200/406mm | 1270m |

| PET-1680 | 16.0mm | 0.80mm | >450kg | 20kg | 18.5kg | 200/406mm | 1080m |

| PET-1610 | 16.0mm | 1.00mm | >520kg | 20kg | 18.5kg | 200/406mm | 970m |

| PET-1970 | 19.0mm | 0.70mm | >0kg | 20kg | 18.5kg | 200/406mm | 1020m |

| PET-1910 | 19.0mm | 1.00mm | >700kg | 20kg | 18.5kg | 200/406mm | 740m |

| PET-1912 | 19.0mm | 1.20mm | >850kg | 20kg | 18.5kg | 200/406mm | 660m |

Customized Service for PET Strap Making Machine

We provide a full range of technical support and services for our PET Strap Making Machine. Our team of experts are always available to answer any questions you may have, help troubleshoot any issues, and provide technical advice to ensure that you get the most out of your machine. Our comprehensive service package includes:

We understand that a reliable technical support and service package is essential for getting the most out of your PET Strap Making Machine. Our team of experts are ready to help you maximize your machine’s performance and efficiency.

|

|

PET Belt Extrusion Equipment 300-350KG/H Automatic Winding PLC Control Images |